ASTM Pipes & Fittings

Plumbing Solutions for Hot & Cold Water Supply (Authorised Dealer Supply)

We supply high-quality Finolex ASTM Pipes & Fittings designed for hot and cold water plumbing systems in residential, commercial, and industrial buildings.

As an authorised dealer, we ensure genuine ASTM products suitable for varied pressure requirements, easy installation, and long-lasting performance.

Key Features

- Conform to ASTM standards for plumbing

- High pressure & temperature resistance

- Corrosion & chemical resistance

- Smooth internal surface for consistent flow

- Reliable joints with compatible fittings

Applications

- Hot & cold water plumbing systems

- Residential & commercial buildings

- Industrial fluid transport

- Pressure water systems

Sizes, Pressure Classes & Standards

Manufactured as per applicable ASTM & IS standards for plumbing applications.

- Wide range of diameters

- Multiple pressure classes

- Compatible fittings for leak-proof joints

Advantages

- Strong & durable under pressure

- Low maintenance & long service life

- Suitable for hot & cold water applications

- Consistent and reliable joint performance

ASTM Pipes

PVC-U ASTM Pipes

Schedule 40 & 80

Heavy Pressure Plumbing Pipes

15 kg/cm² – Conforming to IS 4985

Technical Details

Pipe Derating Factor

PVC-U ASTM Plumbing pipes can be used at higher pressure ratings for a water temperature of 23°C. As the temperature of water increases, the working pressure reduces (100% at 23°C, 50% at 45°C and 22% at 60°C). Pipes may be used up to 45°C without adverse effect.

| Service Temperature (°C) | 23 | 30 | 35 | 40 | 45 | 50 | 55 | 60 |

|---|---|---|---|---|---|---|---|---|

| % of Working Pressure | 100 | 90 | 75 | 62 | 50 | 40 | 30 | 22 |

Thermal Expansion

Thermal expansion of PVC is approximately 4.5 to 5 times higher than metallic pipes. For buried cold water lines there is no adverse effect, however exposed pipelines and high temperature fluids require expansion consideration.

δl = α × L × δt

- δl – Change in length (mm)

- α – Coefficient of linear expansion of PVC

- L – Length of pipe (mm)

- δt – Difference between ambient and operating temperature

Jointing Procedure

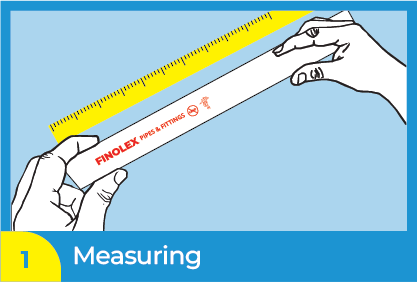

1. Measuring: Measure the required pipe length and mark accordingly.

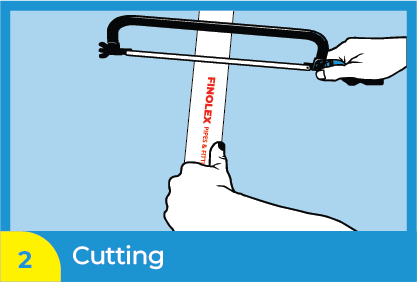

2. Cutting: Pipe must be cut square. Angled cuts may cause leakage.

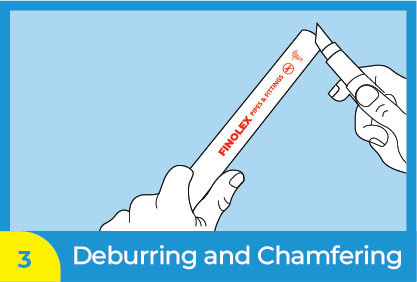

3. Deburring & Chamfering: Remove burrs and apply 10°–15° chamfer.

4. Cleaning: Clean pipe and fitting surface using dry cloth.

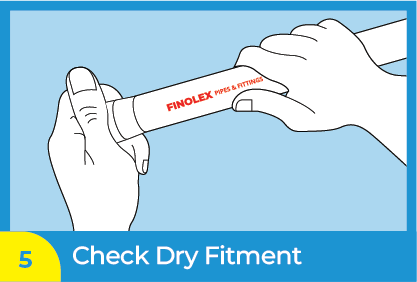

5. Check Dry Fit: Insert pipe one-third to half into socket.

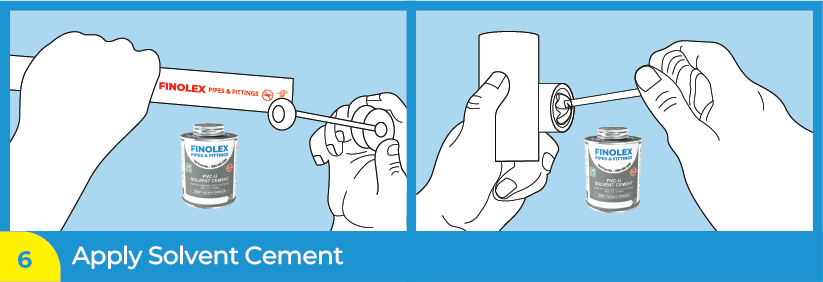

6. Solvent Cement: Apply cement evenly to pipe and fitting.

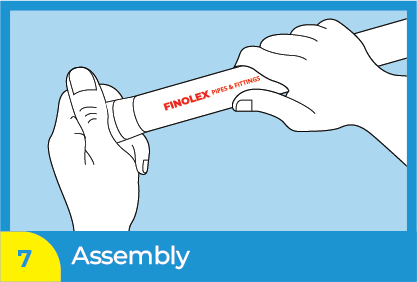

7. Assembly: Join pipe fully and hold till cement sets.

Average Initial Set Schedule

| Temperature Range | ½”–1¼” | 1½”–2” | 2½”–8” |

|---|---|---|---|

| 16°C – 38°C | 2 min | 5 min | 30 min |

| 5°C – 16°C | 5 min | 10 min | 2 hrs |

| -18°C – 5°C | 10 min | 15 min | 12 hrs |

Average Joint Cure Schedule

| Temperature Range | ½”–1¼” | 1½”–2” | 2½”–8” | |||

|---|---|---|---|---|---|---|

| ≤11 | 11–22 | ≤11 | 11–22 | ≤11 | 11–22 | |

| 16°C – 38°C | 15 min | 6 hrs | 30 min | 12 hrs | 1.5 hrs | 24 hrs |

| 5°C – 16°C | 20 min | 12 hrs | 45 min | 24 hrs | 4 hrs | 48 hrs |

| -18°C – 5°C | 30 min | 48 hrs | 1 hr | 96 hrs | 72 hrs | 8 days |

Why Buy From Us?

- Authorised Finolex Dealer

- 100% Genuine ASTM Products

- Dealer Level Pricing

- Bulk & Retail Supply

- Fast Local Delivery

- Product Selection Support